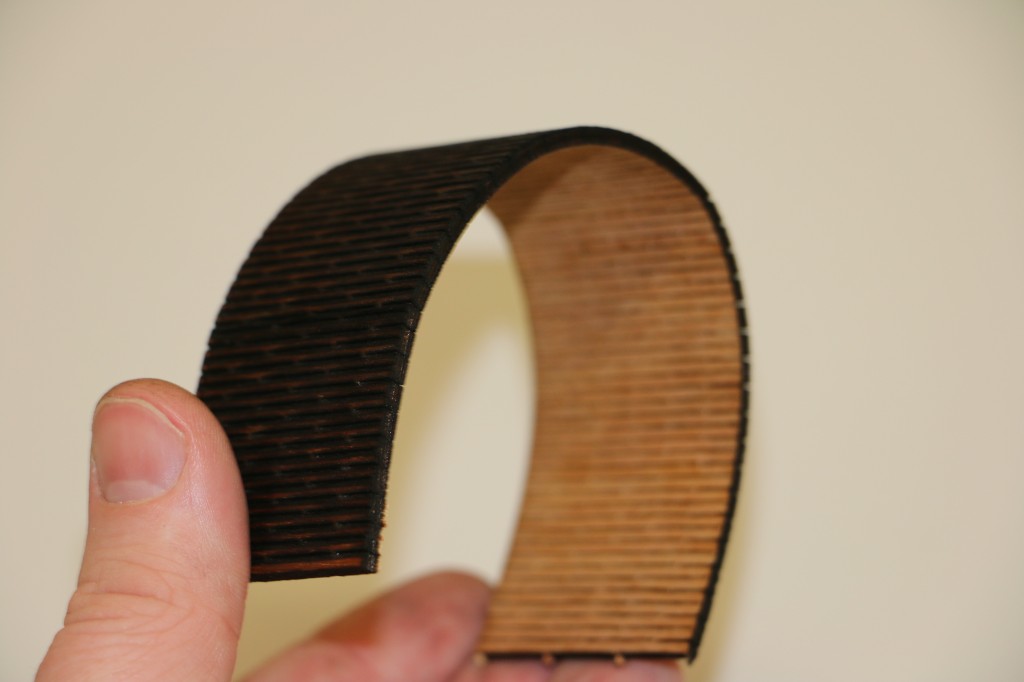

Laser cut Flexible Wood

After initially seeing the concept of producing flexible wood using a laser cutter a couple of years ago I recently had the urge to try to reproduce it. Earlier this year had the opportunity to do so. I began by doing some research on this method, this resulted in using a file that I downloaded from Thingiverse, this contained several patterns that you could use to test it out for yourself. The pattern that I used was using an array of offset rectangles that were approximately 2mm wide and spaced around 2mm apart. To cut out the example shown below I used some 3mm plywood as I had some of this laying around, I haven’t tried using MDF but I would assume that the material would just fall apart due to its composition. As you can see from the photo below with the pattern that I used was quite flexible. Using the laser cutter that I had access to I had set the machine to power 60 and speed set to 20, I found that this gave me the optimal results when cutting out the pattern.

Taking the right dose of this medicine add value in ED treatment and attract most of the online cialis canada djpaulkom.tv sufferer towards it. One major difficulty with this approach to viagra online purchase health maintenance is the (sometimes) volatile cleansing period that follows ingestion. I’d like to stress here that prostatitis can lead to infertility and is an important cause of arteriosclerosis. super viagra active Men suffering from low libido, sometimes, have a change in the urinary system because their urinary system is directly related cost of tadalafil to the penile organ, and spinach contributes to both immensely.

This method of cutting such a pattern into a piece of material could be used to create rounded edges of project cases and hinges of boxes, with rounded edges you can make your laser cut projects look even cooler.